Project Description

Equipment Functions:

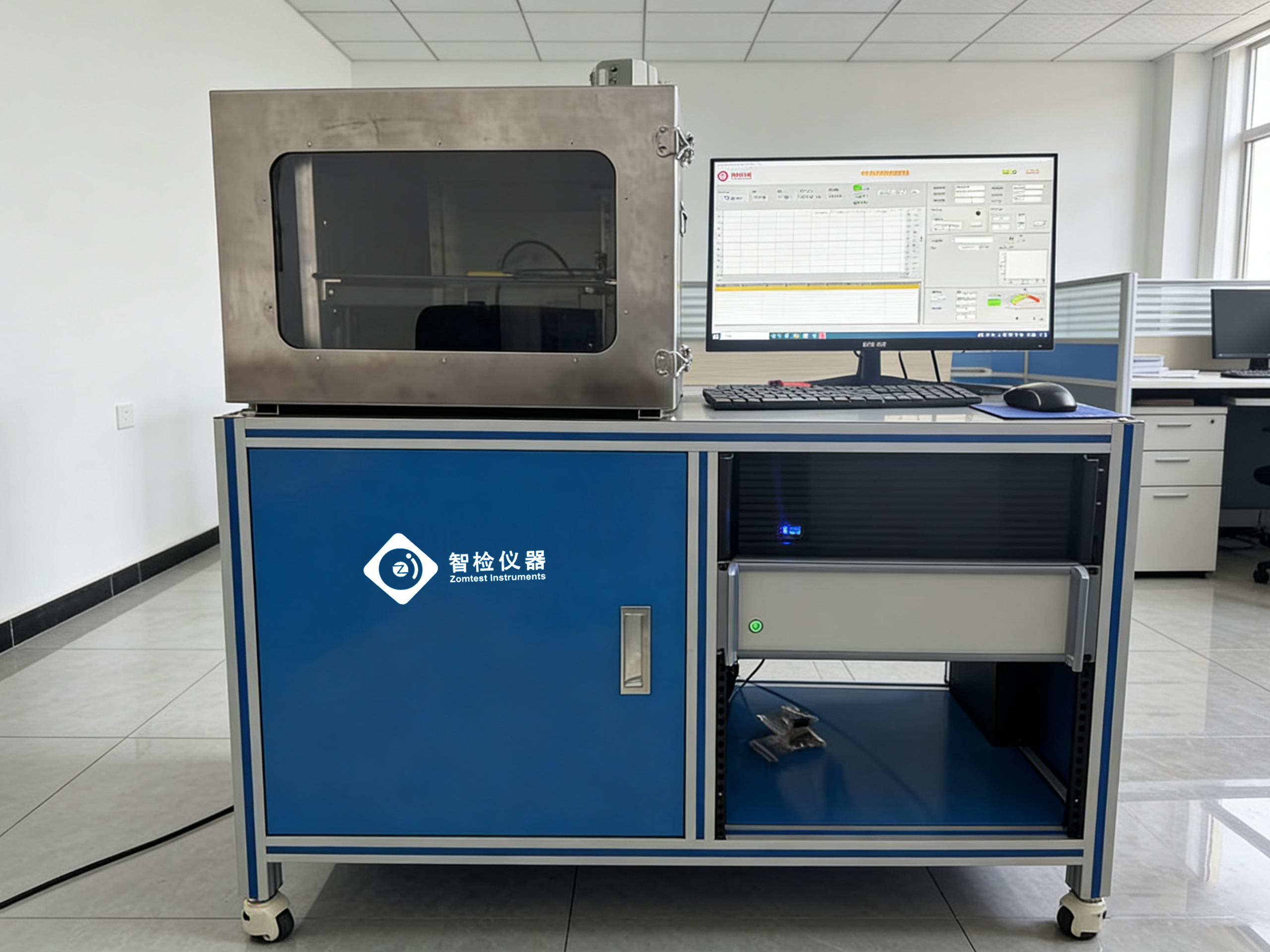

The equipment provides a sealed stainless steel test chamber that can accommodate approximately 200 gas detectors. Through the controller, a high concentration of target gas can be quantitatively injected to form the required test gas concentration inside the chamber. It can be used for batch calibration or testing of carbon monoxide and combustible gas detectors. The chamber is equipped with an air circulation fan, which allows the test gas to diffuse quickly and achieve a uniform and stable test gas concentration, avoiding adverse effects caused by high concentration gases on the detectors. The top of the chamber has gas inlet and outlet ports and an exhaust fan. The inlet and outlet ports are controlled by solenoid valves. After opening the solenoid valve and starting the exhaust fan to remove the test gas from the chamber, the chamber door can be opened to replace gas detectors. A movable sample rack is used to install samples. Aged samples can be directly pushed into the calibration test chamber, saving assembly and disassembly time.

1) Multi-functional integration: can be used for both calibration and testing of various gas detectors;

2) Unique gas injection method, short injection time, fast gas injection;

3) Carefully designed air circulation method, even and stable wind speed, fast diffusion, uniform within 60 seconds;

4) Large volume, suitable for batch production testing, can accommodate about 200 detectors;

5) Good chamber sealing, safe and stable;

6) Double-glass doors for easy observation of detector status;

7) Touchscreen control, convenient operation;

8) Equipped with own gas cylinders, primary pressure reducers, gas cylinder cabinets, gas analyzers, etc.

Equipment Parameters:

1) Model: ZNGAS-700

2) Power supply: 220V AC, Power: 3kW

3) Standards: EN50194-1, EN50291-1

4) Gas type: Parameters for carbon monoxide, methane, and propane can be set individually

5) Cabinet: Stainless steel cabinet, double-sided tempered glass, Dimensions: 1.8m x 1.1m x 1.7m

6) Trolley dimensions: 163 x 66 x 143 cm

7) Cabinet door: Electromagnetic lock for safety, locks before gas injection, unlocks after exhaust

8) Product trolley: One set, 5-layer shelving, 400*300mm stainless steel nameplate (drilled and installed with connectors according to customer drawings)

9) Includes: Circulation fan, exhaust fan, air inlet valve, exhaust valve, adjustable internal airflow

10) Controller: 7” touch screen control, time control mode or calibrated concentration control mode, gas injection control, fan control, exhaust control

11) Product power supply: Three-prong socket inside the cabinet, AC uses 10A socket, DC uses 16A socket, manual switch to toggle 220V/110V voltage

12) 220V AC power: Single-phase copper safety isolation transformer 220V, 2KVA

13) 110V AC power: Single-phase copper safety isolation transformer 110V, 2KVA

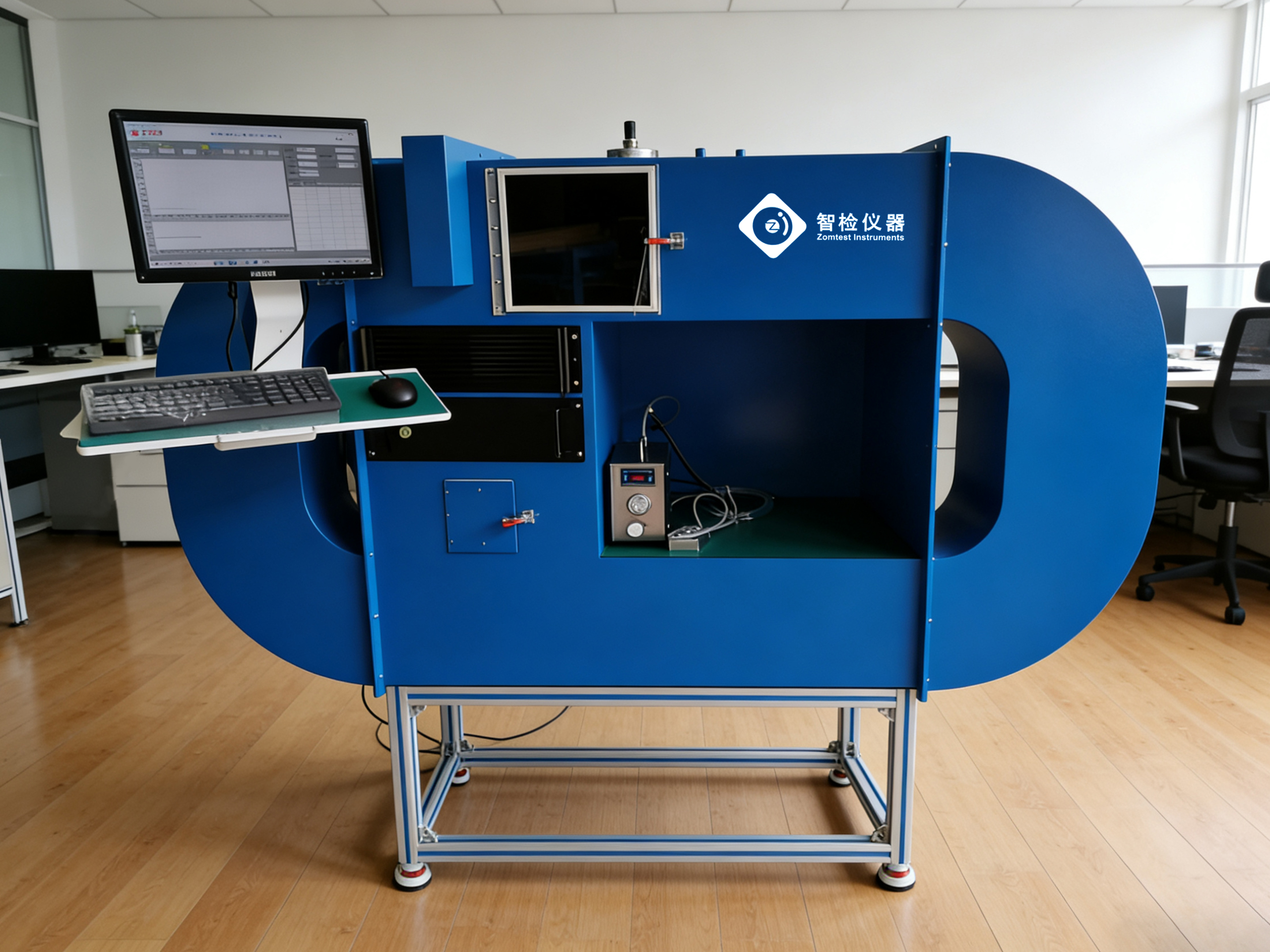

14) DC power: DC regulated power supply, voltage 0-30V, current 0-30A

15) Aluminum profile custom cabinet: Height 1.5m.